Paper

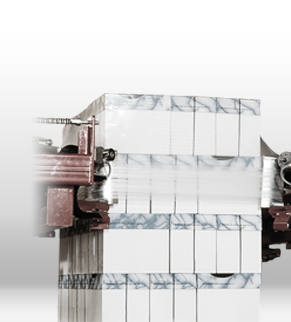

Paper boxes wrapped with Lachenmeier stretch bags.

To minimize the risk of contamination and potential food hazards, produce boxes must be well protected against rain, dust and dirt. Historically, corrugated boxes for the agriculture industry have been wrapped with top sheets, poly bags or throw bags, sometimes combined with stretch wrapping. These conventional bagging and wrapping methods are very slow, and they don't protect the boxes very well.

In 2004, Lachenmeier introduced a corrugated version of the Multi Flex XL, which is designed for maximum flexibility to handle a large variety of unit sizes. The corrugated Multi Flex XL can be configured for 24 second cycle times, and thus wrap 150 units per hour.

Lachenmeier has delivered over 20 machines to various box plants making produce boxes. The system has proven to increase output significantly. Some box plants have doubled and even tripled their output after implementing a Lachenmeier Multi Flex. The corrugated Multi Flex eliminates any issues with bottle necks, which are very common when using hand bags or stretch wrapping.

High Speed Wrapping

Check out our flexible stretch hood wrapping machine Multi FleX1 for high speed wrapping.

Read more about the Multi FleX1 stretch hoodMore important, the stretch bags offer significantly better packaging features and better protection than poly bags and stretch wrapping. The stretch bags fit tightly on the unit, whereas loose poly bags get caught by the wind, which exposes the products to the outdoor elements. When using poly bags, the boxes at the bottom of the units are commonly damaged by rain. The stretch bags are applied to cover the pallets for better rain protection.

With the Lachenmeier stretch bags, the product is completely protected against the outdoor environment, and the boxes are excellently protected for outdoor storage and flatbed shipping.