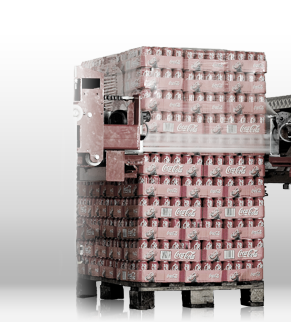

Beverage packaging

For all beverage packaging needs: Can packaging, bottle packaging, kegs and tetra packs with no deformation!

Beverage applications require specific wrapping configurations based on:

- Product and container type

- Filling temperature

- Pressure in the container (especially important for non-carbonated beverages in PET bottles)

- Type of secondary packaging (cluster pack, fridge pack, trays, shrink pack, etc.)

- Use of Hot Melt or Lock N'Pop

- Possible condensation in carton packs

- Palletizing pattern

- Stacking requirements

- Shipping and handling conditions

Lachenmeier stretch hood can be configured for very high holding forces and thus improve the load stability. The improved holding forces can reduce freight damage significantly compared with stretch wrapping. The Lachenmeier wrapping equipment can be configured to release the film at the pallet or below the pallet, which will unitize the load with the pallet and thus reduce the risk of the load sliding on the pallet. Lachenmeier has developed a technology, which can utilize very high friction films, which further improves the load stability compared with stretch wrapping.

The beverage industry is highly competitive. Consequently, it is very important to maintain focus on minimizing packaging costs, minimizing waste and maintaining a high productivity level. More important, it is crucial to ensure that the product is wrapped with a consistent and effective method, which ensures that the product arrives at its destination without transport damage.

We analyze the requirement for load containment based on the parameters above, and the pallet wrapping configuration will be perfectly balanced between cost and specific need for pallet containment.

Please see our packaging system for beverages. The flex wrap solution Power Flex T1. The Multi FleX1 flexible for multiple pallet sizes.

Small but powerfull

Check out our packaging system, the Power Flex T1. The perfect machine for products with minor variation in size.

More about our Power Flex T1