Load stability for Fiber Fuels

Fiber fuels generally come in two forms, a wood pellet and a brick. Pellets are usually packaged in 40 or 50 pound plastic bags, or in bulk bags. Bricks are typically stacked and palletized. Both products are placed on pallets, then a large top sheet or bag is placed over the loads to help prevent the product from getting wet or dirty. Once covered, the load is wrapped with stretch film to help hold the top sheet or bag on the load. The other purpose of the stretch wrap is to help stabilize the load. This is the most common way of wrapping these load types, but not the most efficient, cost effective, or best way to stabilize them.

Using top sheets and bags to cover the loads is very inefficient and expensive. In many cases it’s a manual operation, which is time consuming and costly. In some cases top sheets and bags are automatically placed on the loads with inline equipment. This type of equipment is not very reliable, due to wind or breezes inside the plant blowing the film and bags off the loads during application. More often than not, this equipment become an inefficient bottleneck and is commonly bypassed. When this happens, placing the top sheets and/or bags over the loads, again becomes a manually operation.

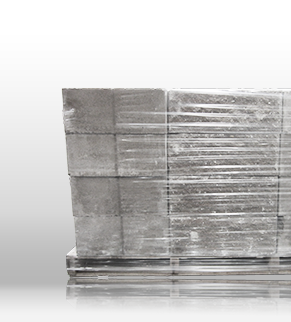

Lachenmeier’s stretch hooding system is a much more efficient way of wrapping these loads. It offers better load stability, costs less per load and provides a much nicer visual package. The stretch hooding process starts with the machine, which uses a polyethylene gusseted tubular film. The film is automatically measured for length and sealed at the top to create a fived sided enclosed protective hood for the load. The protective hood has no layers, unlike stretch wrapping, so there is no risk of water and dirt running down between the layers of film, potentially damaging the product and negatively altering the load appearance. The hood is also smaller than the load, which reduces the amount of film consumption per load. It relies on its elasticity and memory characteristics, along with the machine, to stretch open the hood, apply it down over top of the load. The hood can be released on or under the pallet for optimum load stability.

Both products, wood pellet and wood bricks, present their own challenges, however one more difficult than the other. Wood brick loads are easy to stabilize, because they nest well and are not very tall loads. Wood pellets are more challenging, because of the load instability due to tall heights, ranging in heights from 48 inches to sometimes 96 inches or more, depending on the supplier. Slick plastic bags and overhang of the loads on the pallet also present challenges. As a result, conventional stretch wrapping methods experience problems trying to provide the proper load stability that is needed for this industry. Lachenmeier’s stretch hooding system is the proper wrapping solution for this industry.

In order to be successful with wrapping fiber fuel/wood pellets and tall loads in general, the equipment being used must have the flexibility to adjust to the tall loads and the product overhang that is commonly found with these loads. Lachenmeier’s Multi FleX1 stretch hood machine has that flexibility. Our patented film unwinding during stretch feature (#US7040076), allows us to properly stretch the film, prior to applying it. This process reduces the amount of film consumption per load, provides more film thickness on the corners for extra holding force. It also helps control how the film is being applied, achieving maximum load integrity. For more demanding situations, where extra rough handling may be an issue, Lachenmeier equipment can apply unique wrapping patterns to the load for extra reinforcing and stabilization needs.

Lachenmeier’s stretch hooding solution is a one machine, one step process. It saves on production line space, because of a small machine footprint and the elimination of upstream top sheet machines, or bag placers. The equipment has less moving parts than most stretch wrapping systems and requires fewer steps to properly wrap the load. As a result, the overall cost per load is reduced, because there is no manual labor involved, it eliminates the need for top sheets or bags, no pop conveyors needed to release the film under the pallet, no need for trucking tarps, reduced maintenance, etc. The Lachenmeier system is extremely reliable, very efficient and highly recommended for this industry.

Read more about wood pellets wrapping

Small but powerfull

Check out our packaging system, the Power Flex T1. The perfect machine for products with minor variation in size.

More about our Power Flex T1